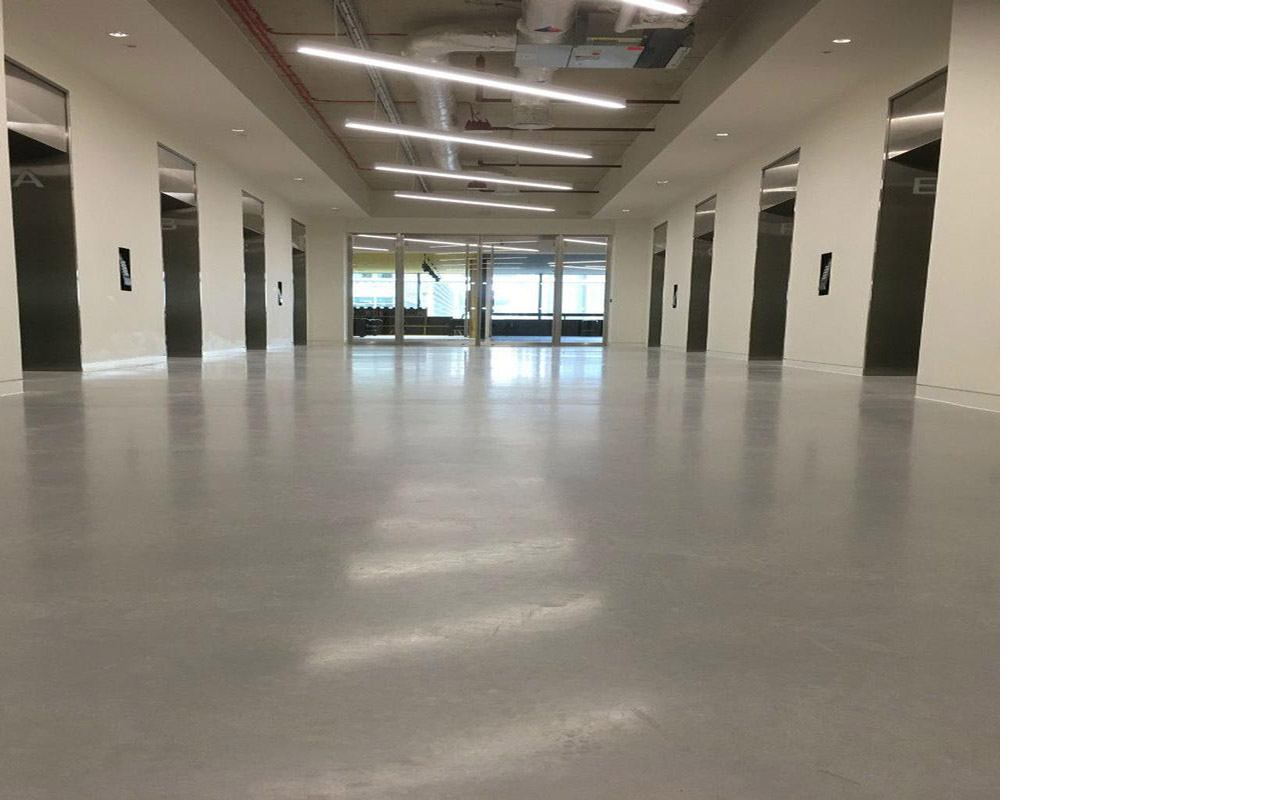

Puur PSR Polished Concrete

Product Description

Puur PSR Polished Concrete Overlay is designed to provide a 'power floated concrete style' of floor finish. Designed to be laid at just 6mm over screeds/tiles/ply/cement boards. Puur PSR is polymer modified and heavily fibre reinforced. Puur PSR can be specified in any RAL or NCS colour, including over fifty shades of grey. Puur PSR is mixed and poured in situ, up to 1000m2 can be poured seamlessly.

Technical Specification

Installation:

Standard 6mm (nominal 3mm-maximum 20mm)

Colour:

Natural (white) or pigmented with any RAL classic or NCS colour.

Slip resistance:

Regular finish dry R12 or wet R11